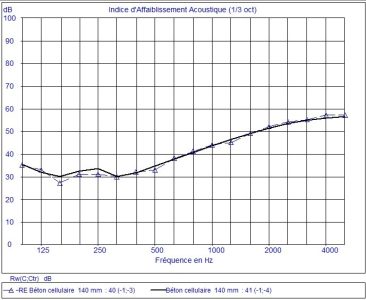

Cellular concrete 14 cm :

- Cellular concrete 14 cm

- Calculation : RW = 41

- Measure : RW = 40

Home › Software development › AcouS STIFF®

AcouS STIFF® is software used for predicting the sound reduction index. Our program complies with ISO 717-1, NFS 31-051 and ASTM-E413 standards. In addition to our tutorials, our team teaches you how to use AcouS STIFF®.

Our inter-company training courses take place online but can also be carried out in your offices on request anywhere in France and abroad. They teach the participants the basics that will serve to highlight the influence of the parameters that can be used to optimize a structure.

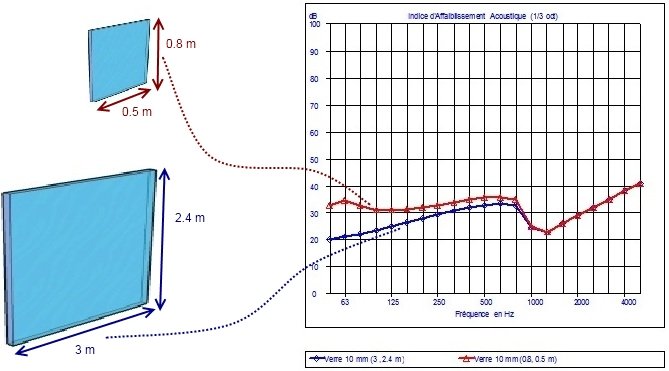

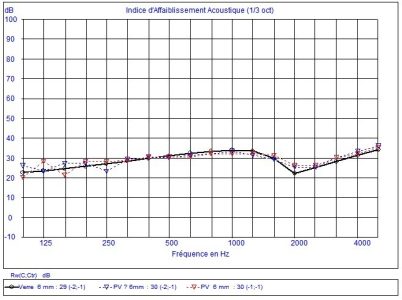

R as a function of embedding dimensions of the glazing

The sound reduction index of a wall can be measured in a laboratory specially designed for this purpose (decoupling of sending and receiving cells, shapes and sizes of cells, ....).

However the sound reduction index of a wall depends on a very large number of parameters. One naturally thinks of the thickness, or density of constituent materials, but particularly variable settings from one application to another, such as length and width of the panels are also of great importance, as evidenced by the following figure :

Under these conditions, the number of walls to be tested is infinite and a uniquely experimental approach, by the time and cost it represents, can not suffice.

Predicting then appears as an essential complementary approach.

Complex wall structure simulation

Acous STIFF® acoustic software is a simple and adapted tool that allows you to :

The results are presented as graphs and /or tables showing the overall values in accordance with ISO717-1, NF S 31-051 and ASTM E 413.

AcouS STIFF® acoustic software can perform calculations of forecast reduction index of the following types of walls :

In addition, one can perform the following operations on the sound reduction indexes :

The following mechanical connections are distinguished:

For the same wall, there can be several types of connection between the outer facings.

There are two types of basic components in AcouS STIFF®:

This element is solid, homogeneous, isotropic, rectangular is shape, its thickness is small compared to its lengths and widths and also before the wavelengths of play, especially in solids.

Subsequently, this only works in Plate bending : no shear wave, surface compression...is taken into account.

It also represents a barrier which is supposed to be completely airtight; the speed of a particle of air on the Plate is equal to the speed of the plate at the point. Which distinguishes it fundamentally from the other basic component, the Porous.

Important parameters :

It consists of a solid element or an aggregate of solid elements with blank spaces that could be saturated by a fluid. It presents itself as the assembly of two phases :

All porous materials characterized by such behavior in the acoustic software AcouS STIFF® are permeable to air, for example, foams are open pores.

Indeed, the acoustic behavior of closed-cell foam (e.g. polystyrene) is of the type Plate. This is the fundamental difference between the two basic components.

Important parameters :

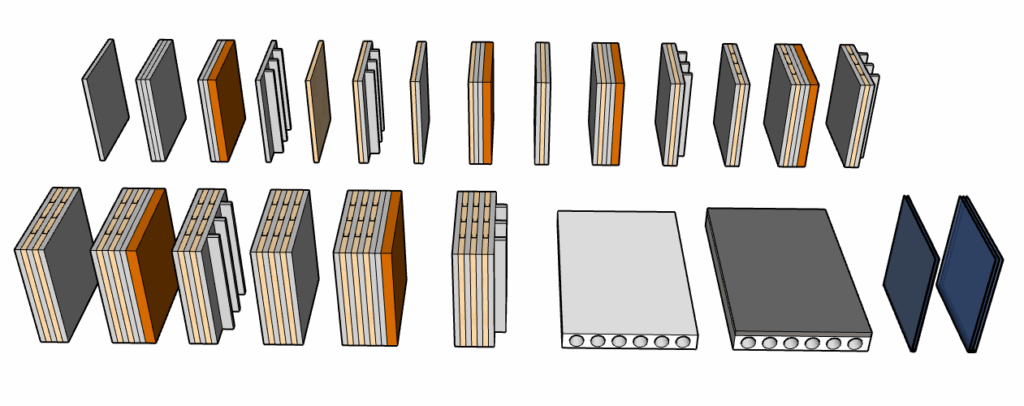

Check out some examples of possible arrangements with AcouS STIFF® software.

This list is not exhaustive.

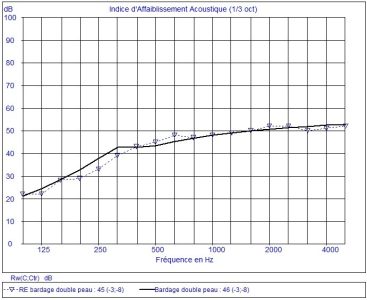

Double skin :

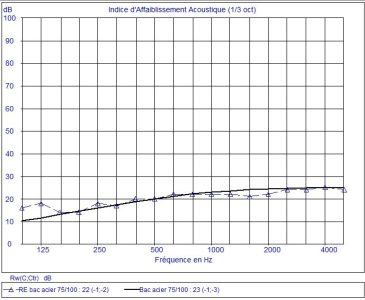

Steel deck 75/100 :

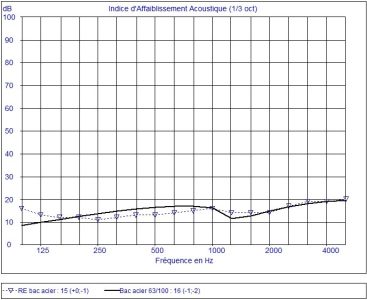

Steel deck 63/100 :

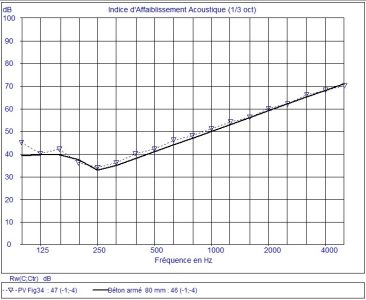

Reinforced concrete 8 cm :

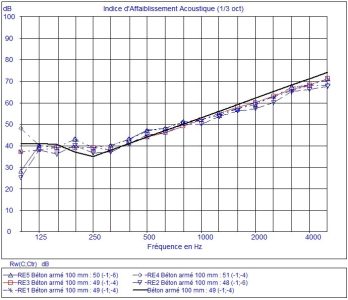

Reinforced concrete 10 cm :

Cellular concrete 14 cm :

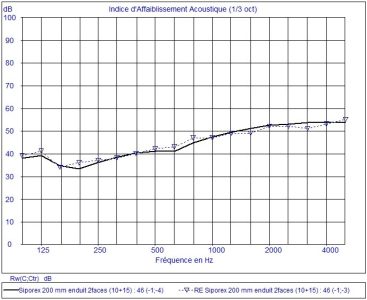

Cellular concrete 20 cm :

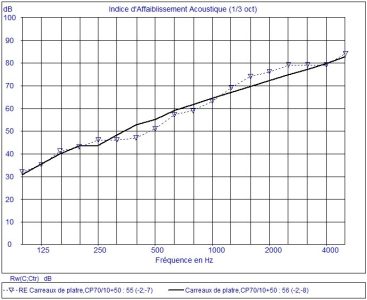

Doubling on gypsum :

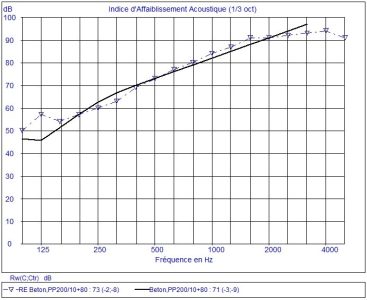

Reinforced concrete 20 cm :

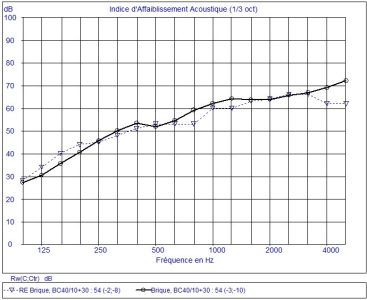

Doubling on Brick :

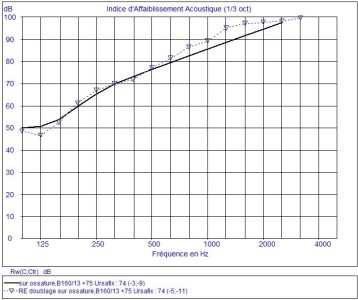

Doubling on frame :

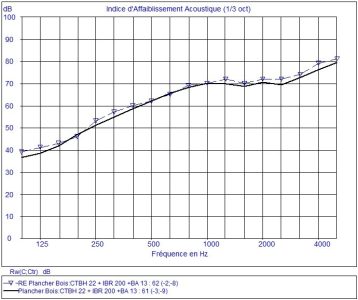

Wood floor :

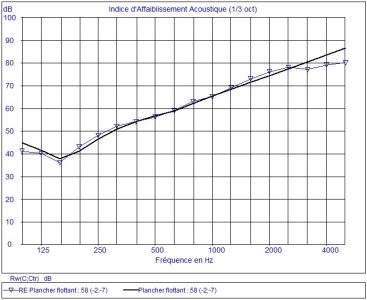

Floating floor :

Single glass :

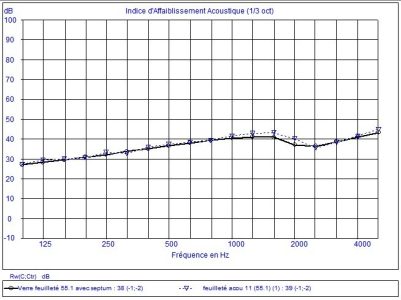

Laminated glass :

Double glazing 44.2/20/55.2

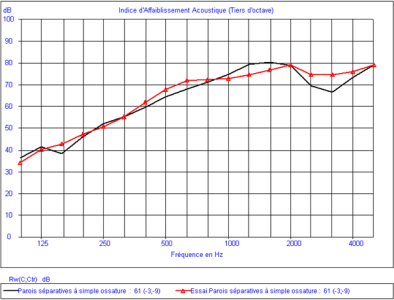

Single-frame walls:

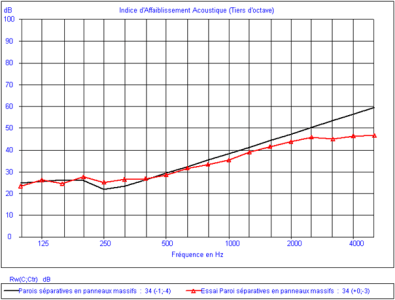

Dividing walls in solid laminated panels:

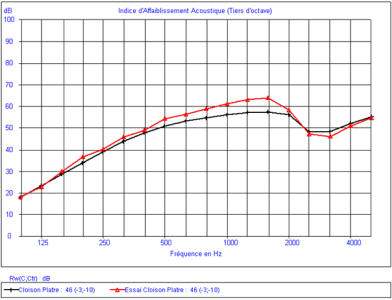

Gypsum wall:

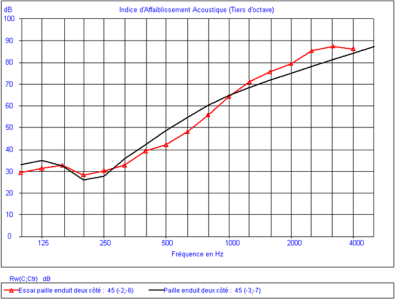

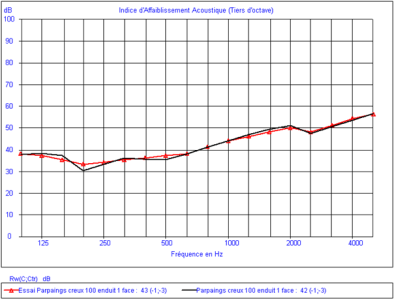

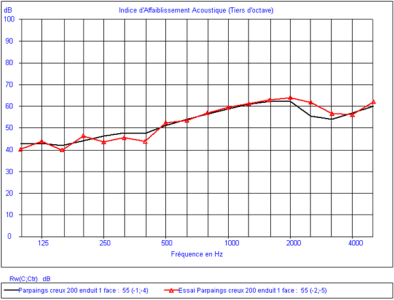

Hollow block 100 coated on 1 side:

Hollow block 200 coated on 1 side:

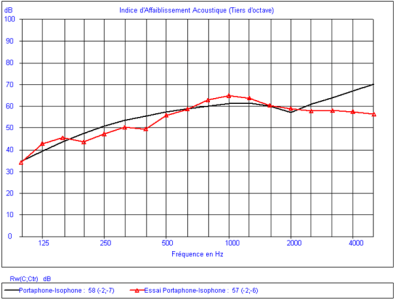

Isophone-portaphone door

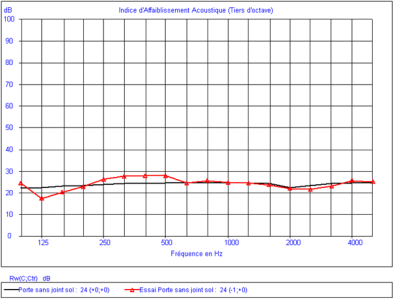

Door without floor seal:

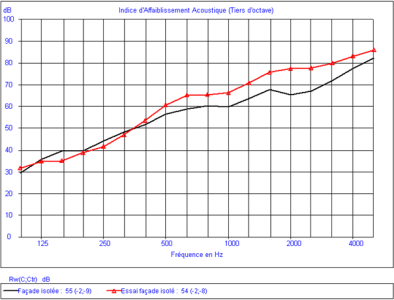

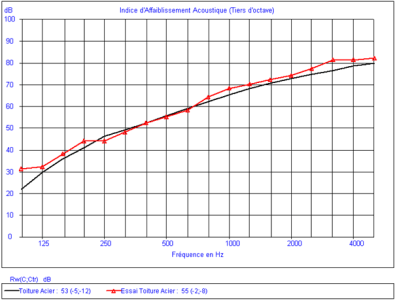

Steel roof:

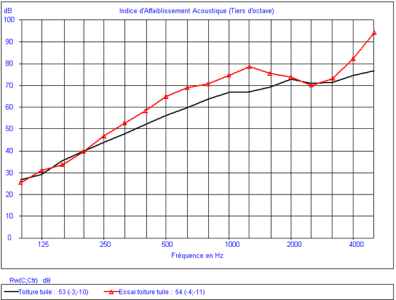

Tiled roof:

The AcouS STIFF® software, developed by GAMBA Group, simulates the sound reduction index of complex walls.

This tutorial is an overview of this software.

How to simulate the sound reduction index of partitions with plasterboard and insulation with AcouS STIFF® software ? Tutorial by GAMBA Group

Training goals : :

People concerned : :

The course is valuable for engineers who design or prescribe the walls, including :

For further information, please contact Marion Lorin

For all our software, a complete range of products and services is at your disposal :

This maintenance contract provides among other things : the maintenance of the software and the dongle, the delivery of software updates for free for holders of the maintenance contract, phone support, special discounts on other software

Each year a new version containing additions or changes in the software is available.

We regularly organize inter-company and intra-company training courses on the use of the software.

Each year and each software program, at least one day of information and discussion is held with the users of such software.

We can do calculations of acoustic simulations on request with the use of our software. You can avail of these services free or at very favorable terms for an annual fee.

For more information, please contact us

You will find below answers to some questions you ask and which we hope will give you the information you seek.

The software can model all types of wall partitions, walls floors, roofs.

Yes, the overall values in Rw (C, Ctr), dB(A)/pink, dB(A)/road, and STC are calculated according to national and international standards (ISO 717-1, NFS 31-051, ASTM E413,...)

Yes, the software calculates the global indices such as the U.S. STC (Sound Transmission Class).

Yes, the software comes with a database covering the most common materials and widely used in France and Europe.

Yes, just create simple or porous siding in a file from the database, give the name of the component that you want and enter its physical characteristics (density, Young's modulus and factor loss for material type "plate" and resistivity to air flow for porous materials with open pores).

Yes, they can be displayed in tables and on graphs. This data is customizable via context menu "Properties" window "Reports" tab "View" and "Results".

Yes, they can be displayed on graphs via context menu "Properties" window "Reports", "View" tab.

Yes, you can import your RE packet or one by one from a spreadsheet (like Excel, Open Office,...); workbook for that use context menu "Paste RE (Import spreadsheet)" the window "Walls Explorer".

I confirm that STIFF® can calculate perforated sheets.

Yes, you can define leakage percentages for the panels.

AcouS STIFF® allows to take into account that direct transmissions on the other hand we have another calculation module called AcouS STICS 21® who is in the test phase which allows lateral transmission calculations to be made.

Yes directly in the Windows file manager like any other file or create another with "File" then "new file"? Yes.

From the glazing module, it is possible to model the two glazings making up the double joinery. These two simulations will give you the characteristics to enter in the triple wall (if double glazing and monolithic glazing) or your quadruple wall (if two double glazing) modeling your double joinery.

To make the simple walls, you just have to go through the materials tab, select the different materials, you "drag and drop" from the materials tab to the wall construction window and so it will create the simple walls for you.

The insulation calculation model (DnT and L'nT) is based on the ISO 12354 series of standards which itself is based on the assumptions of the SEA for the analytical approximations. For the wall prediction models (R and Ln), the models depend on the subjects, they are taken from the literature and are analytical models of behavior.

We have generic biosourced materials, but no specific brand in BDD.

But you can very well simulate the products mentioned, we do it by the way.

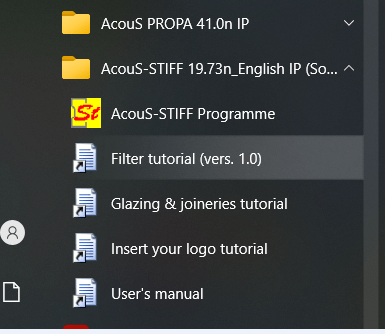

Yes, you have at your disposal after downloading manuals and tutorials on each software. (see picture below)

You can also contact us directly by telephone on 05.62.24.36.76